During laser cutting of sheet metal with oxygen, a brown to black oxide layer is formed at the cutting edges. If the oxide layer on the sheet edge is not removed after the laser treatment, this usually leads to quality problems during the subsequent processing steps (painting, galvanizing, powder coating).

A stable connection of paint, zinc or powder coating with the sheet metal is not possible in areas with an oxide layer. Even a small impact load can lead to large-area spalling of the paint, zinc or powder coating.

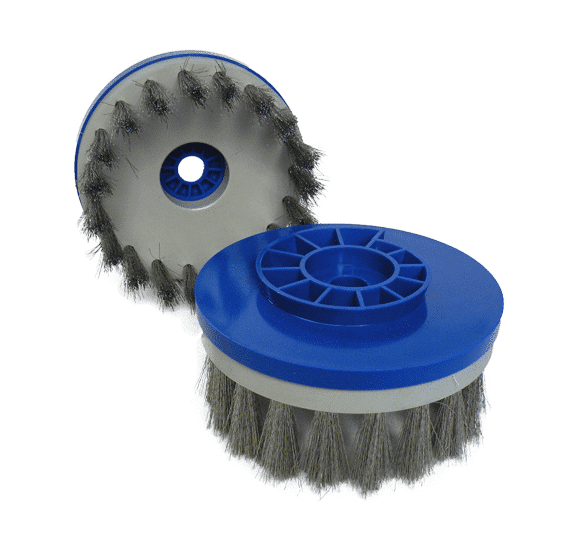

The solution is to remove the oxide layer from the inner and outer contours of the workpieces in an upstream machining process. This is best done with our oxide layer brush FAPI-TRIM.

Product features

The oxide layer brush FAPI-TRIM shows excellent properties in use:

- Oxide free cutting edges

Despite the quite flexible fill, the oxide layer brush FAPI-TRIM aggressively attacks the oxide layers with the bristle tips. This causes them to flake off so that the oxide-free cutting edge on the sheets, which is important for the subsequent machining processes, is created.

- Long service life

FAPI-TRIM oxide film brushes have a very long service life. When correctly positioned on the machine, the oxide layer brush FAPI-TRIM does not suffer any fatigue breakage of the bristles.

- A wide range of fill materials

By selecting different fill types, densities and lengths, the machining process can be decisively influenced. The optimum design of the oxide layer brush FAPI-TRIM must be determined on the basis of the material to be processed and the sheet thickness.

- Made in Germany

Without exception, all Picard tools and of course our oxide layer brushes are produced in Germany. High-quality and optically outstanding brushing tools are our production result, from which you as our customer benefit.

Mountings

FAPI-TRIM

Ø 115 mm | CW

Ø 125 mm | CW+CCW

FAPI-FIT

Ø 150 mm | CW+CCW

FAPI-150

Ø 150 mm | CW+CCW

FAPI-250

Ø 250 mm | CW+CCW

*CW = clockwise rotation | CCW = counter-clockwise rotation

Dimensions

| Diameter [in mm] | Extraction type | Trimming thickness [in mm] | Stocking height [in mm] | Maximum speed [n max] | Application |

|---|---|---|---|---|---|

| 115 | VA-wire | 0,20 | 30 | 2.000 1/min | Dry/Wet |

| 115 | HSS steel wire | 0,20 | 30 | 2.000 1/min | Dry/Wet |

| 115 | VA-wire | 0,30 | 30 | 2.000 1/min | Dry/Wet |

| 115 | HSS steel wire | 0,30 | 30 | 2.000 1/min | Dry/Wet |

Other dimensions on request!

Applications

The removal of oxide layers from cutting edges of sheet metal parts with the oxide layer brush FAPI-TRIM is carried out on automatic stationary deburring machines (e.g. Weber deburring machines).

dry processing

wet processing

flame-cut parts