Burrs occur when sheet metal is punched, plasma cut, laser cut, torch cut, etc. With the development of our deburring wheels and deburring rollers FAPI-FLEX, we have successfully addressed the challenge faced in operations to deburr or round the “sharp” edges on workpieces. With the use of these highly versatile tools, both with portable machines and automatic machines, sheet metal can be rounded or deburred optimally.

Our engineers and application technicians are available for you at any time by phone or email.

Product features

- Extraordinary increase in service life

The use of our specially developed deburring wheels and deburring rollers FAPI-FLEX has led to an extreme increase in service life. In practical use it has been proven that, our deburring wheels and deburring rollers have twice or three times the service life compared with conventional wheels and rollers.

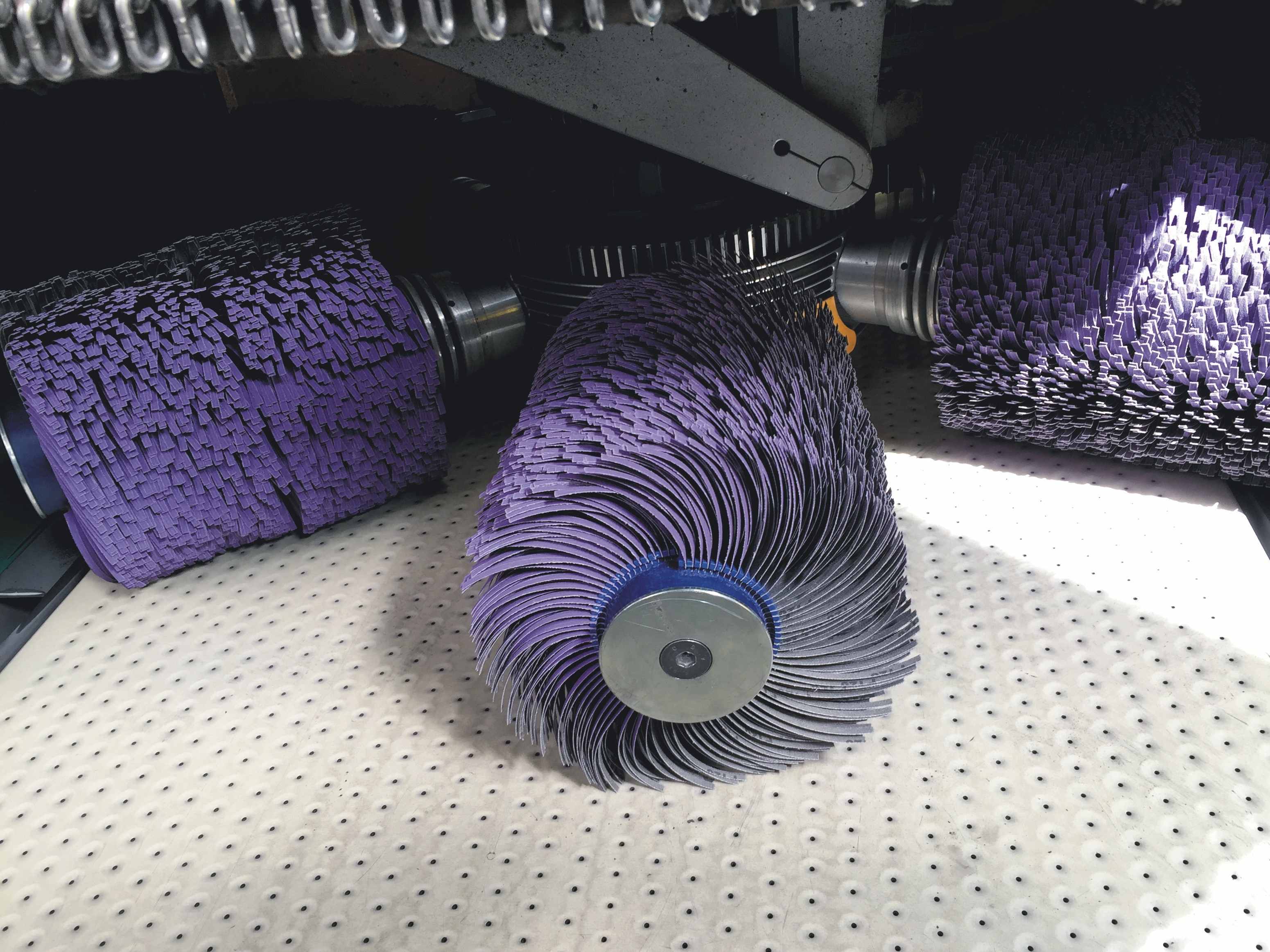

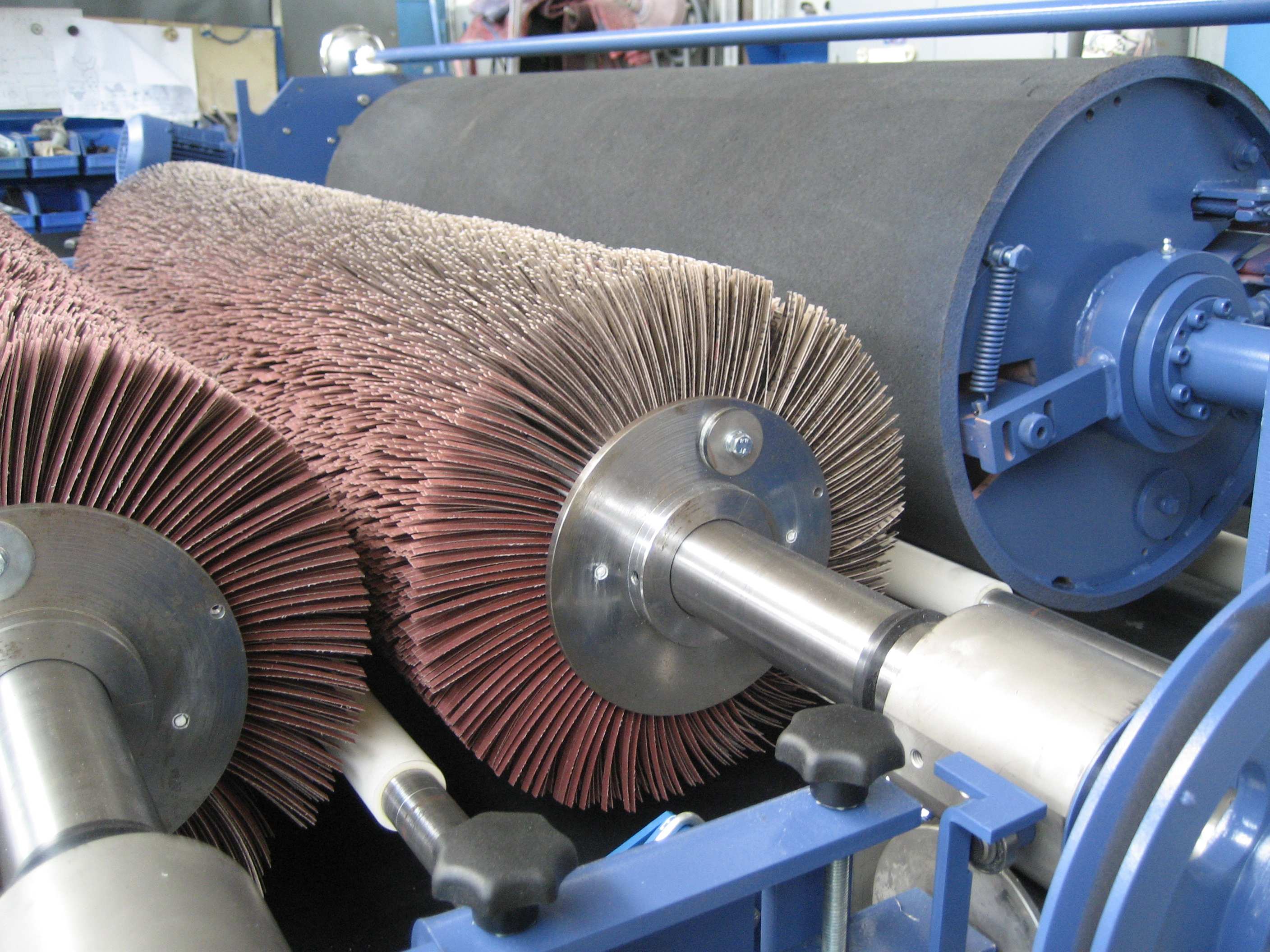

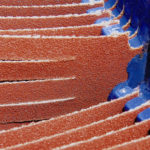

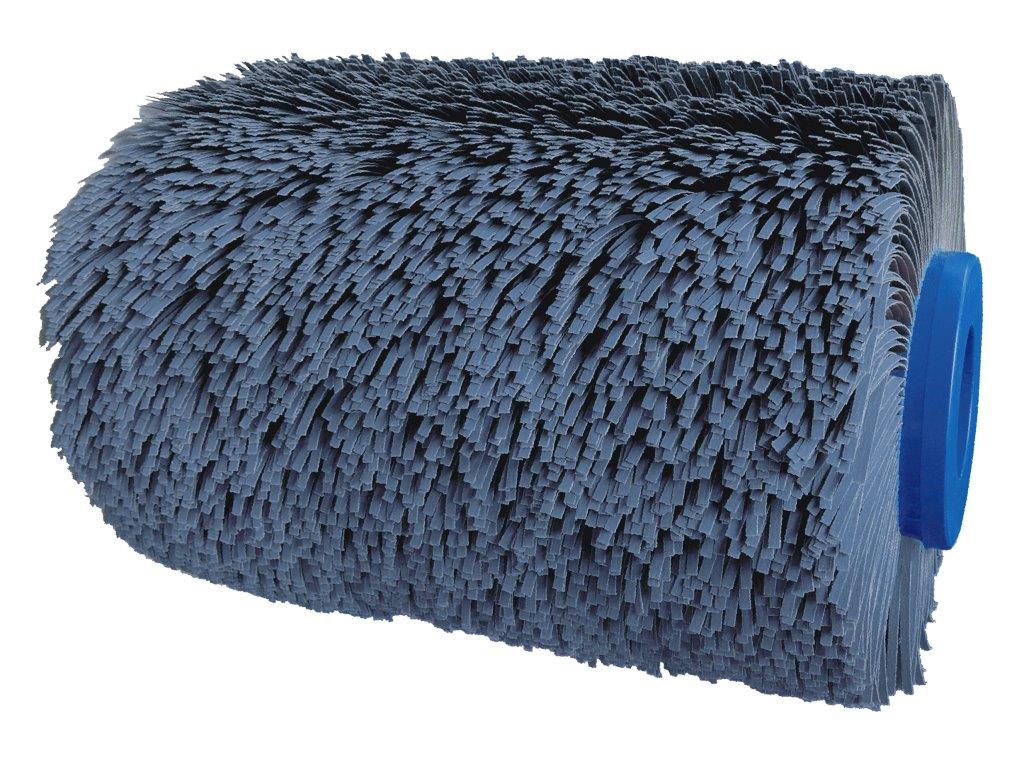

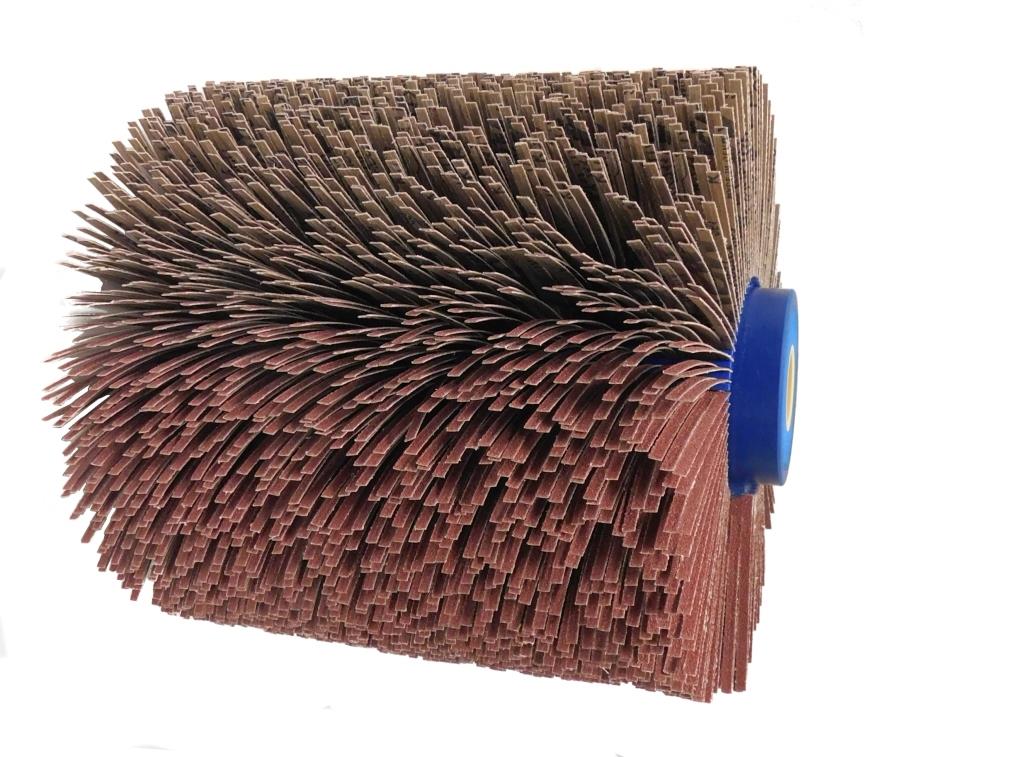

- Axial arrangement of the grinding flaps

The grinding grain sides of the slitted abrasive cloth flaps are arranged axially on the roller. The knocking against one another of the grinding grain sides and the resulting premature destruction of the grinding facing, which occurs when the abrasive cloth flaps are arranged radially, is avoided.

- Short equipment set-up times

The easy assembly or disassembly of the machines allows extremely short set-up times.

- Extremely high abrasive cloth rate

An extremely high abrasive cloth rate on the deburring wheels and deburring rollers FAPI-FLEX results in a significant improvement in service life.

- Variable Dimensions

It is possible to manufacture deburring rollers in various densities, facing lengths and abrasive cloth types.

- Versatile areas of application

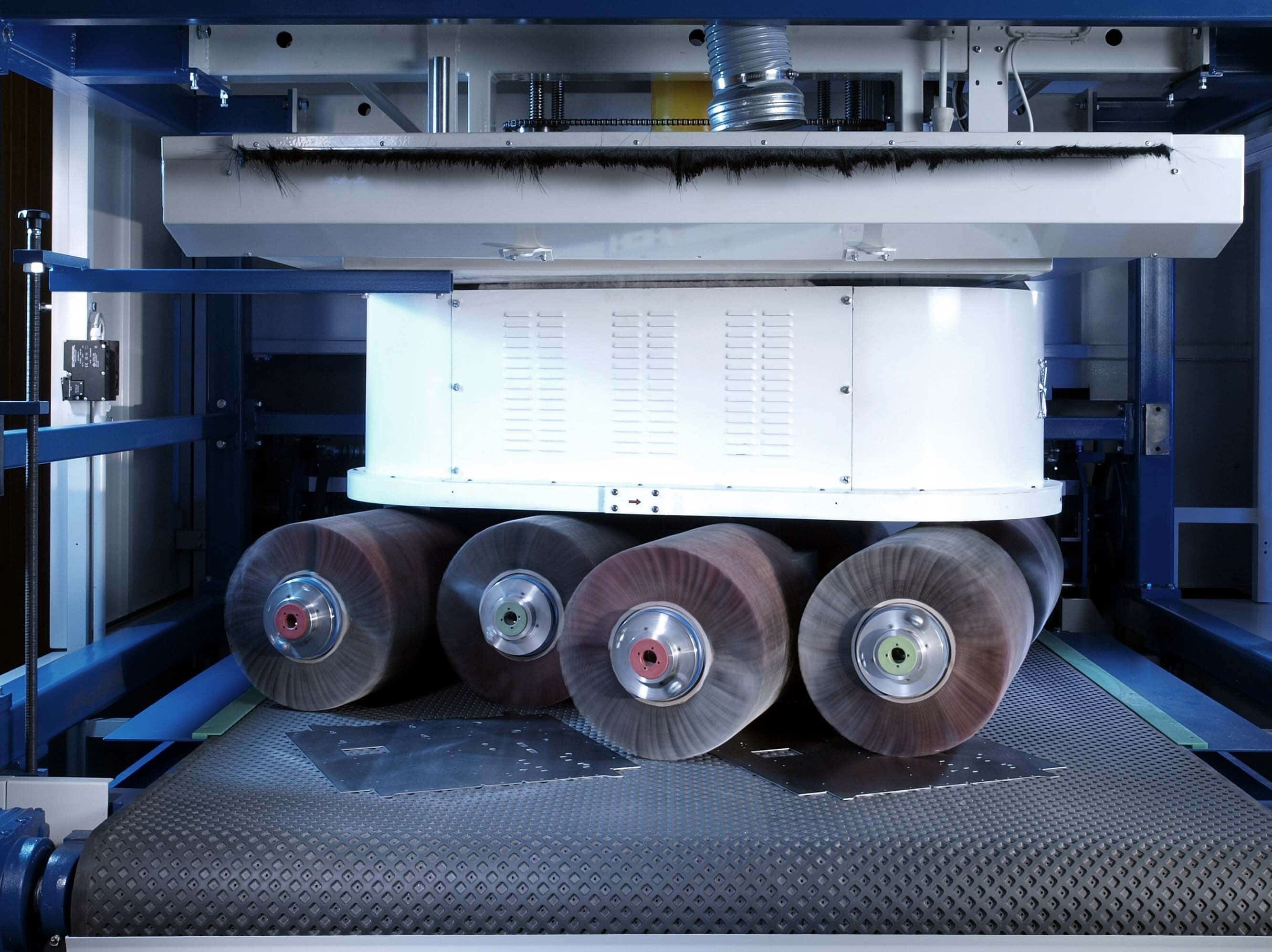

The deburring wheels and deburring rollers FAPI-FLEX are used with portable machines as well as with carousel grinding machines and two or multi-roll roller grinding machines.

- Special abrasive cloth flap designs

As a standard, the deburring wheels and deburring rollers FAPI-FLEX are provided with abrasive cloth flaps which are continuously slotted.

As special design, the possibility exists to produce the abrasive cloth flaps with disconnected slits – the so called bridge slot. Thus results in achieving a better surface on small workpieces while using the deburring wheels and deburring rollers.

- Cost-benefit-relationship

The cost-benefit-relationship of the deburring wheels and rollers FAPI-FLEX is optimally laid-out for our customers.

Facing types

Variable facing types

FAPI-FLEX

STANDARD

FAPI-FLEX

GAP

FAPI-FLEX

WAVE

FAPI-FLEX

COARSE

FAPI-FLEX

SHINE

We have the right dimensions for your deburring machine! Please see below a small excerpt of the available tool dimensions.

Finishing variants individually adjusted to your process – for a perfect result!

Deburring rollers FAPI-FLEX (For Timesavers machines)

TYPE: ROTOR 42 series 1350er – 42 series 1000er – 32 series 1100er

Dimensions

Diameter: 300 mm / 350 mm

Total width: 312 mm / 490 mm / 1000 mm

Hole: 80 mm / 135 mm

Deburring rollers FAPI-FLEX (For Weber machines)

TYPE: MRB = multi rotating brushes

Dimensions

Diameter: 250 mm (1100er / 1350er / 1600er)

Total width: 250 mm (1350er + 1600er) / 300 mm (1100er)

Hole: 80 mm

Deburring rollers FAPI-FLEX (For FLADDER® machines)

TYPE: AUT / GYRO

Dimensions

Diameter: 300 mm / 350 mm / 400 mm

Total width: 262 mm / 340 mm / 350 mm

Hole: 32 mm / 100 mm / 200 mm

Further machine-specific dimensions possible!