The most diverse and very individual design possibilities are possible with Vulkollan® coated components.

Joints between Vulkollan® and metal can be easily produced after pretreatment of the metal component. During this pre-treatment, the surface of the component is cleaned and degreased using a sandblasting process. Subsequently, the application of an adhesion promoter guarantees an optimum bond.

The metal component (e.g. steel, aluminium, cast iron) assumes the function of a stable supporting body.

The Vulkollan® coating meets the highest performance requirements in terms of wear protection, damping and noise reduction.

Product features

The material Vulkollan® is characterized by outstanding properties that make it interesting for a variety of applications:

- Award-winning mechanical wear resistance

- High impact elasticity, even with hard settings

- High tear propagation resistance

- Low compression set

- Good resistance to mineral oils, greases, petrol and various solvents

Applications

Metal compounds with Vulkollan® are used in many areas of industry where high performance requirements are placed on the coating:

- Coatings for Wheels, Rollers and Rollers

- Balls with solid or hollow metal cores

- Coatings of valve seats

- linings, skirting boards and throwing shovels with fixing reinforcements

- Pipe cleaning pigs with steel or magnetic cores

- Suction cup, gripper and sealing frame with metal adapter

Technical data

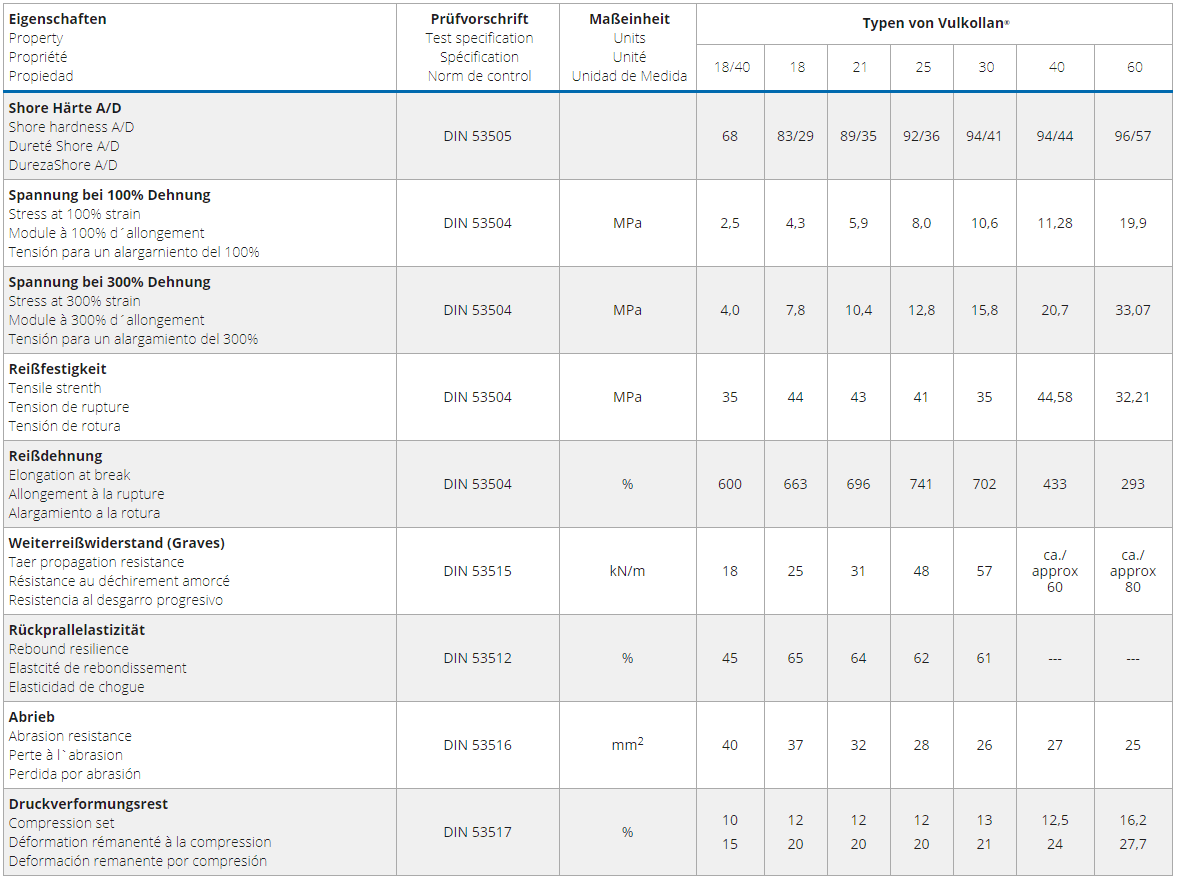

| Properties property propriété Propiedad | Test procedure Test specification spécification Standard de control | Unit of measure units unité Unidad de Medida | Types of Vulkollan® | ||||||

|---|---|---|---|---|---|---|---|---|---|

| 18/40 | 18 | 21 | 25 | 30 | 40 | 60 | |||

| Shore Hardness A/D Shore hardness A/D Dureté Shore A/D DurezaShore A/D | DIN 53505 | 68 | 83/29 | 89/35 | 92/36 | 94/41 | 94/44 | 96/57 | |

| Stress at 100% elongation Stress at 100% strain Modules à 100% d´allongement Tensión para un alargarniento del 100% | DIN 53504 | MPa | 2,5 | 4,3 | 5,9 | 8,0 | 10,6 | 11,28 | 19,9 |

| Stress at 300% elongation Stress at 300% strain Modules à 300% d´allongement Tensión para un alargamiento del 300% | DIN 53504 | MPa | 4,0 | 7,8 | 10,4 | 12,8 | 15,8 | 20,7 | 33,07 |

| Tear Strength Tensile strenth Tension de rupture Tensión de rotura | DIN 53504 | MPa | 35 | 44 | 43 | 41 | 35 | 44,58 | 32,21 |

| Stretch at Break Elongation at break Allonment à la rupture Alargamiento a la rotura | DIN 53504 | % | 600 | 663 | 696 | 741 | 702 | 433 | 293 |

| Graves resistance Taer propagation resistance Resistance to the amorphous decision Resistencia al desgarro progresivo | DIN 53515 | kN/m | 18 | 25 | 31 | 48 | 57 | approx 60 | approx 80 |

| rebound elasticity rebound resilience rebondissement elastometry Elasticidad de chogue | DIN 53512 | % | 45 | 65 | 64 | 62 | 61 | --- | --- |

| Abrasion Abrasion resistance Perte à l`abrasion Perdida por abrasión | DIN 53516 | mm2 | 40 | 37 | 32 | 28 | 26 | 27 | 25 |

| Compression set Compression set Rémanenté Déformation à la compression Deformación remanente por compresión | DIN 53517 | % | 10 15 | 12 20 | 12 20 | 12 20 | 13 21 | 12,5 24 | 16,2 27,7 |