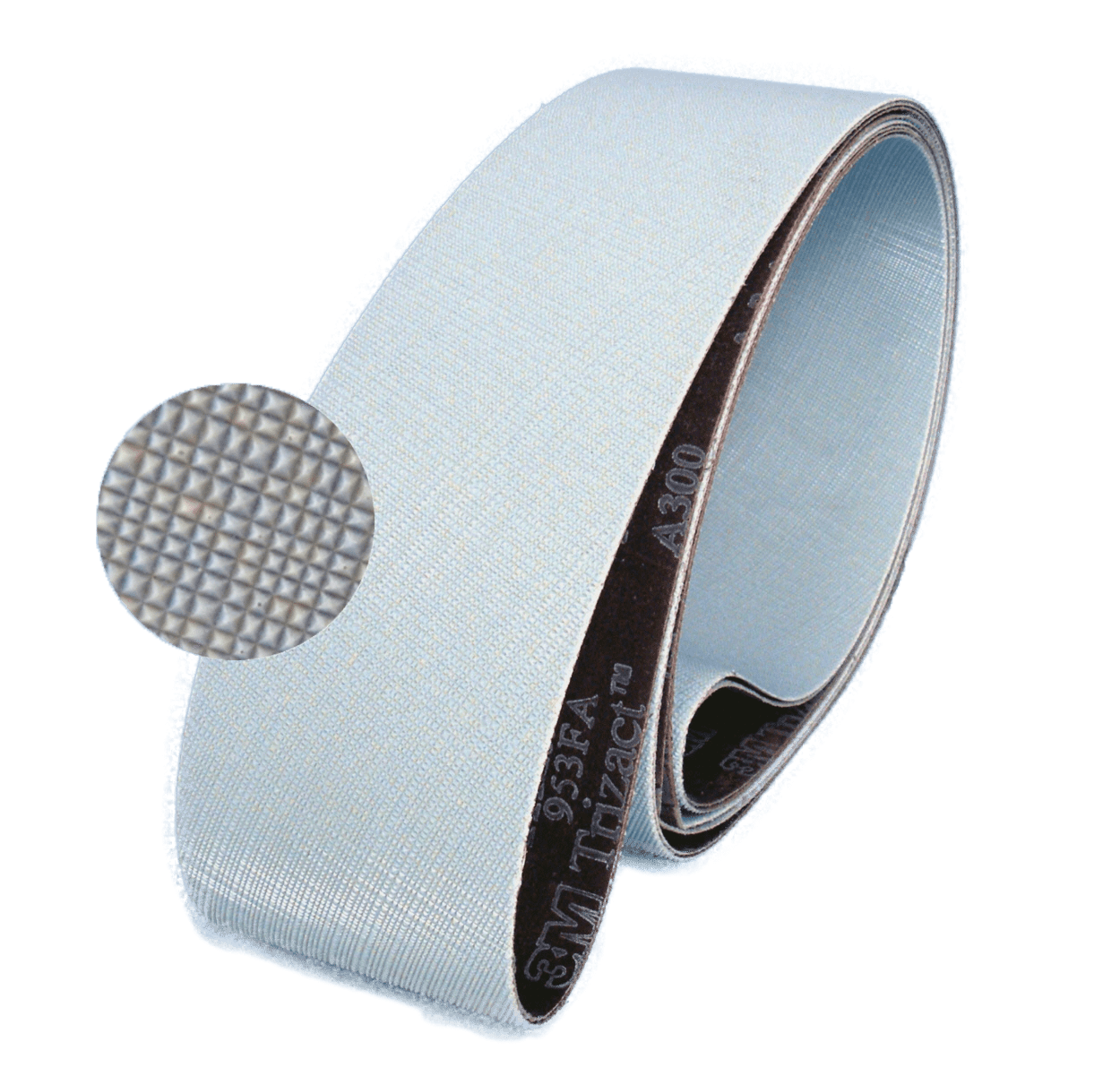

Abrasive belts Trizact™ have been tried and tested abrasives in companies for years. With the pyramid-shaped structure and the three-dimensional abrasive layer of Trizact™, these abrasive belts can be used to produce an outstandingly fine grinding pattern despite their extreme stock removal rate. The structure of the abrasive guarantees a permanently uniform removal during the entire grinding process.

Often several steps can be saved by using grinding belts Trizact™ . Thus, the Trizact™ principle makes a decisive contribution to increasing quality, reducing costs and at the same time shortening delivery times in the companies.

Grain size comparison

The designation of the Trizact™ grain size differs from the grain size according to FEPA. For a better allocation and selection of the correct grit size for the Trizact™ abrasive belts, a grit size comparison is shown in the table below.

| Grain size comparison | |||

|---|---|---|---|

| Trizact™ A | grain size FEPA | Trizact™ A | grain size FEPA |

| A6 | 2000 | A80 | 240 |

| A16 | 1200 | A90 | 220 |

| A20 | 1000 | A100 | 220 |

| A30 | 600 | A110 | 180 |

| A40 | 500 | A130 | 150 |

| A45 | 400 | A160 | 120 |

| A60 | 320 | A300 | 80 |

| A65 | 280 | --- | --- |

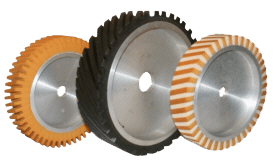

Picard tip: Correct choice of contact wheel

In order to achieve the full performance of the grinding belts Trizact™, the correct contact wheel must be selected. For grinding and structuring, contact wheels from the FAPI-PA series with or without small grooves with 40 to 65º Shore are to be selected. For fine grinding or polishing, choose the FAPI-VU series or ideally a lamella contact wheel from the FAPI-VUS series or the FAPI-BW series. As a general rule, a softer contact wheel achieves a better Ra value.