The choice of the ideal satin finishing wheel with the best suited dimensions, facing and hardness must be determined based on the customer’s requirements. We have many years of experience and would be pleased to advise you by phone or email on a high quality and cost-effective satin finishing wheel for your process.

Applications

As a rule the surface treatment of wood takes place with satin finishing wheels which have an silicon carbide facing. Grinding with this facing produces a silky lustre effect on the workpiece’s surface.

Material: Wood

Workpiece type: Profiled or flat wooden parts

Grinding operation: Surface and profile grinding

Handling: automatic grinding, hand-operated machines, grinding by hand

Examples: Mouldings, doors, furniture, intermediate varnish sanding, etc.

Optional cutting speed

To achieve best results, the speed should lie between 15-20 m/s. To achieve a perfect surface on the workpiece, it is recommended that the satin finishing wheel runs as slowly as possible while applying light pressure. Higher speeds and higher pressure reduce both the service life of the satin finishing wheel and the quality of the workpiece surface.

Facing

The following qualities are available in our programme:

| Silicon carbide | Classification grain faction |

|---|---|

| Medium | 150 - 220 |

| Fine | 240 - 320 |

| Very fine | 360 - 400 |

| Super fine | 500 - 600 |

| Ultra fine | 800 - 1000 |

Hardness

Satin finishing wheels are available in a large variety of hardness:

| Hardness grades | Description |

|---|---|

| H3 | soft |

| H5 | medium soft |

| H7 | medium-hard |

| H10 | hard |

| H12 | very hard |

| RAX | extreme hard |

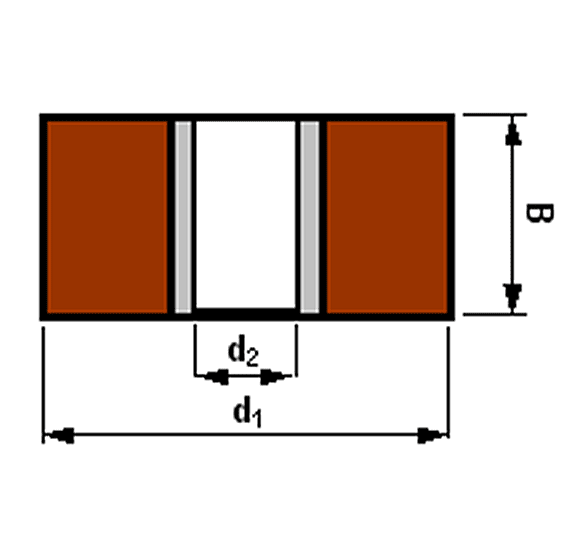

Dimensions

| Ø d1 [ in mm ] | Standard hole d2 [ in mm ] | Width B [ in mm ] | Max. speed [ n max ] |

|---|---|---|---|

| 100 | 25 | All widths between 20 mm and 1.400 mm |

2.900 1/min |

| 150 | 50 | 1.900 1/min | |

| 200 | 76 | 1.500 1/min | |

| 250 | 115 | 1.150 1/min | |

| 300 | 150 | 950 1/min | |

| 350 | 200 | 800 1/min | |

| 400 | 250 | 750 1/min | |

| 450 | 300 | 650 1/min |

The hole can be varied using an aluminium flange system adaptable to the shaft diameter.