The choice of the optimum combined satin finishing wheel with the most suitable dimensions, fill and hardness must be determined according to the customer’s specific application. With our many years of experience, we will be pleased to advise you by telephone or at your site regarding a high-quality and cost-effective combined satin finishing wheel design for your process.

Construction

The combined satin finishing wheels consist of an arrangement of abrasive fleece and abrasive cloth flaps. As standard, they are arranged in a ratio of 1:1. Depending on the application, however, this ratio can be specifically adapted to the application.

Basically, the abrasive fleece can be chosen between an aluminium oxide coated fleece or a silicon carbide coated fleece. While fleece with aluminium oxide is mainly used in metalworking, fleece with silicon carbide is mainly used in woodworking. All commercially available grit sizes can be used for the abrasive cloth.

Applications

In metalworking, the combined satin finishing discs achieve a very high stock removal rate, while at the same time creating a silk matt effect. Combined satin finishing wheels are used exclusively for dry grinding.

Compared to satin finishing wheels, the combined satin finishing wheels stand out due to an increased service life, a different grinding effect (i.e. from line formation to comma line formation) and a stronger silk matt effect.

The combined satin finishing wheels are ideal for machining shaped workpieces.

Further areas of application:

Manufacture of containers and kitchen appliances, coppersmiths, food industry, vehicle construction, stainless steel processing, copper, aluminium, brass, plastics, leather, etc.

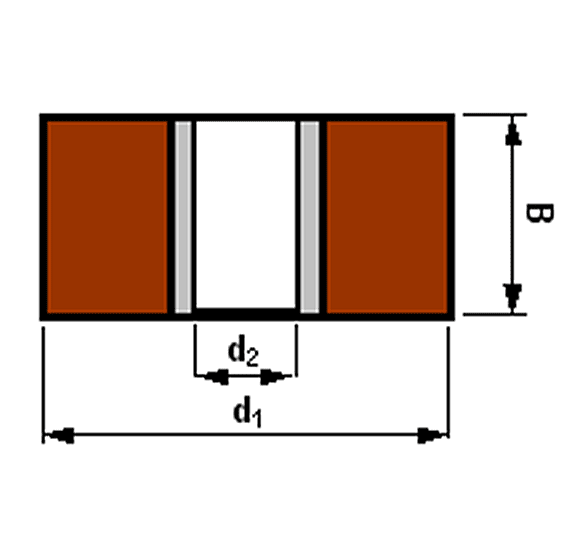

Dimensions

| Ø d1 [ in mm ] | Standard drilling d2 [ in mm ] | Width B [ in mm ] | Max. speed [ n max ] |

|---|---|---|---|

| 100 | 25 | All widths between 20 mm and 1.400 mm | 2.900 1/min |

| 150 | 50 | 1.900 1/min | |

| 200 | 76 | 1.500 1/min | |

| 250 | 115 | 1.150 1/min | |

| 300 | 150 | 950 1/min | |

| 350 | 200 | 800 1/min | |

| 400 | 250 | 750 1/min | |

| 450 | 300 | 650 1/min |

Available versions:

Different packings can be selected.

For example:

1:1 Packaging (structure of the combined satin finishing discs)

1:1 = 1 lamella fleece / 1 lamella abrasive cloth

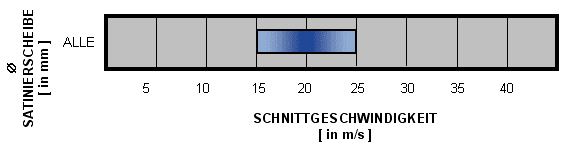

Optional cutting speed

For best results, the speed should be 15-20 m/s. In order to achieve a perfect surface on the workpiece, it is recommended to run the satin finishing wheel as slowly as possible with light contact pressure. Both higher speeds and higher contact pressure reduce the service life of the satin finishing wheel and worsen the workpiece surface.